Why BIG KAISER?

Reducing Production Costs with BIG KAISER—Quality!

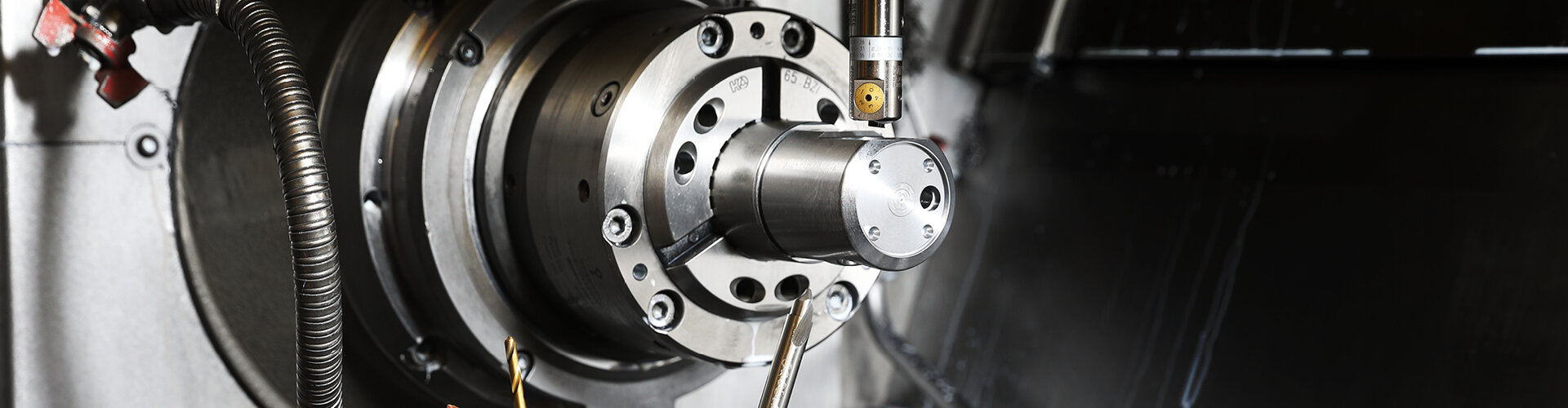

Superior tooling is critical to top-level production performance. BIG KAISER manufactures high performance, high tolerance tooling and delivers it to our customers with a personal commitment to helping them install truly efficient solutions. The result is an all-star line-up of products that deliver true and measurable performance advantages — products that are engineered to exacting standards and then manufactured with materials and craftsmanship that enable superior performance.

We have exceptionally high standards for our products. Not every shop requires extreme accuracy or total efficiency. But for those that do, there is no better partner than BIG KAISER. If your challenge is to manufacture with greater responsibility and accuracy and to find products and processes to improve the efficiency of your applications, call us. It's what drives our business.

PRECISION

BIG KAISER's high-precision tooling guarantees maximum process reliability and reduction of waste.

Just a few of many concrete examples:

- All BIG Collet Chucks are AA-certified and are tested twice for precision.

- BIG KAISER offers self-balancing and balanceable precision boring heads, which are working tremendously accurate even at high power.

- Balanced precision boring head EWB-UP. Ultra-precise diameter adjustment via rough adjustment of the insert holder and fine adjustment with dial scale.

- Change precision of 0.002 mm radial.

PERFORMANCE

The equation is simple: higher power leads to a shorter processing time, which brings financial gain.

Just a few of many concrete examples:

- The MEGA New Baby Chuck line. The collet, ferrule and body are all of absolute precision and exceed the performance of standard ER systems with their reliable and improved concentricity.

- Twin-cutter boring heads SW. Without changing any components and without length adjustment, two different roughing methods, RSS and DVS, can be executed.

- Balanced precision boring head EWB-AL. Made of high tensile aluminum with hard coating. Together with reductions and extensions made in the same way, the weight for long and large diameter tool combinations is reduced by more than 50%. The EWB-AL is designed for cutting speeds up to 2000 m/min and is equipped with a highly accurate self-balancing mechanism.

- Smart Damper anti-vibration products are designed for deep-hole boring with BIG KAISER’s CKB modular boring system, and also for extended reach milling with both inch- and metric-pilot shell mills and face mills.

INNOVATION

BIG KAISER continuously invests in employees and machines to meet the high demands of innovation.

Just a few of many concrete examples:

- BIG-PLUS Spindle System surpasses all other spindle concepts while offering interchangeability with existing machines and tool holders. Click here to learn more about the BIG-Plus Spindle System in direct comparison with a regular Spindle System.

- CKN: The strongest tool connection for lightweight tools. The newly developed double connector coupling enables the use of aluminum extension tubes which result in a weight reduction of up to 50% compared with steel tool combinations.

- Series 318. High precision and light boring.

- Precision boring head EWN 04-7. The smallest precision boring head in the world.

SERVICE

Service at BIG KAISER stands for highest supply from stock, prompt delivery service, decades-long spare parts inventory, competent representations all over the world and complete documentation of all products and cutting parameters.

Just a few of many concrete examples:

- Complete and continuously updated documentation of all products. The documentation consists of multilingual product catalogs, technical data and instruction manuals.

- Know-how next to you: BIG KAISER has highly skilled employees and a distribution network of more than 40 competent representations all over the world. Moreover, BIG KAISER has many own sales representatives in the markets.

- Supply from stock of over 95 percent.