One Step ahead - BIG KAISER Präzisionswerkzeuge | BIG KAISER

One Step ahead

Autoblok relies on the quality of BIG KAISER's chucks to produce its world-renowned workpiece clamping systems. Being able to count on a technological partner like BIG KAISER – with its reliability, precision, range and rigidity – allows Autoblok to focus on production efficiency. This enables it to customize equipment for its customers, giving them a competitive advantage.

Family success story

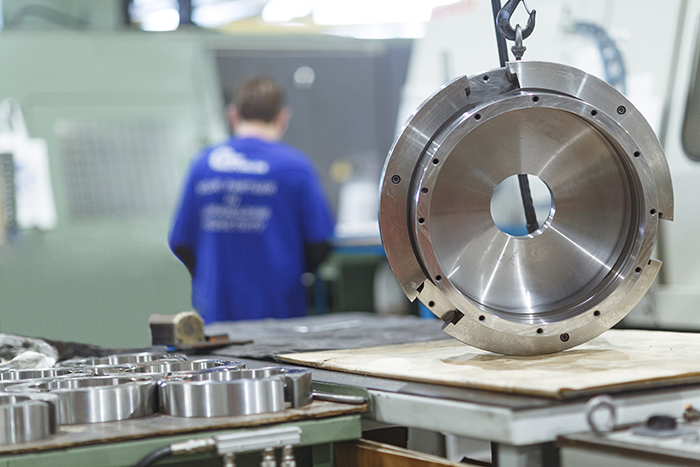

The SMW-Autoblok group is one of the world's leading manufacturers of clamping equipment for turning and milling machine tools, including self-centering chucks and bezels, membrane chucks, expansion chucks and twin vise clamps. Overall, SMW-Autoblok's product catalogue is among the most comprehensive in the industry.

Autoblok was founded in 1942 in Turin by Domenico Bronzino, with the production of manual and automatic spindles. In the '50s, Autoblok went from a workshop serving local companies, to become a fully industrialized manufacturing company, and the first spindle manufacturer in Italy. The '60s saw the marketing of its products abroad and the opening of branches in Europe, United States and then all over the world. The acquisition in 1993 of the German company SMW created the SMW-Autoblok group, recognized today as a world leader in the production and supply of clamping equipment for turning, grinding and milling machine tools.

Autoblok is still led by the Bronzino family. With six production plants in Italy (four in Val di Susa, in addition to OML and Mario Pinto), the SMW plant in Meckenbeuren, Germany, and 18 sales and service branches covering all continents, Autoblok is a success story of Italy’s engineering industry: "Always one step ahead," as the company's motto says.

The turning point of customization

Over the years, Autoblok's equipment production has shifted from standard products to the development of customer-specific solutions. This trend has also led to a structural reorganization of the company, both in terms of production space and specialized personnel.

"Our historical reference market is automotive," says Pier Domenico Bronzino, Operations Manager of Autoblok. "Let's remember, however, that every round piece is usually turned, so it needs to be held." And here the opportunities increase exponentially: from the small bearings used in electric motors to the very large bearings used in wind power, to those used in aerospace and oil and gas, just to name a few examples.

"Today, to be successful you need to be able to accompany the customer through all phases of the project, providing solutions to all their problems,” says Bronzino. “Each of our technical departments can support customers by advising how to lock a part in the machine in accordance with the required tolerances, as well as how to do it as efficiently as possible in terms of cycle time."

"Being able to offer customers a value-added service, such as customizing clamping equipment, has allowed us to differentiate ourselves from the competition," says Bronzino. "We don't simply offer quality products at a market value, but a real tailor-made consultancy that allows our customers to acquire the tools to improve productivity and efficiency. Not everyone is able to provide this kind of service."

On an organizational level, and in line with Industry 4.0 requirements, the enormous wealth of technological knowledge gathered by Autoblok has been made available to all branches. Every single project is in fact uploaded into a database shared by the whole group. This means it is possible to immediately know if a type of part has already been produced in another part of the world, to access the project data and thus drastically reduce development time and time to market.

With BIG KAISER, without worries

Autoblok's production can be divided into three main groups: standard products, application spindles and customizations. The company uses BIG KAISER solutions for all three types, with complete satisfaction, which enables Autoblok to concentrate all its energy on the actual customization project. "BIG KAISER's solutions are really reliable, precise, rigid and efficient – for us it is a guarantee," says Bronzino.

In precision machining, clamping the part is one of the most important tasks. Even the most technologically advanced machine, equipped with the best performing tools, cannot ensure high execution precision when vibrations come into play. This is why it’s essential to clamp the workpiece in the correct position and ensure maximum rigidity.

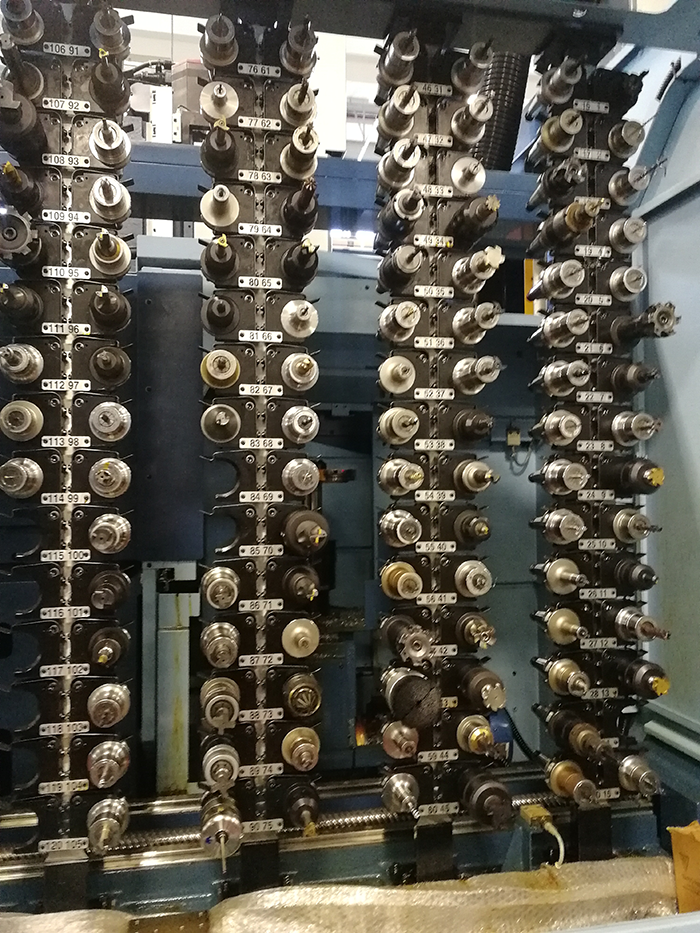

Autoblok's fleet includes more than 100 machines equipped with the BIG-PLUS dual-contact system. This is the only system in the world able to guarantee simultaneous frontal and conical double contact between the machine spindle and the tool holder, and is a BIG DAISHOWA patented exclusive. As a result, the contact between the machine and the tools is extremely solid, ensuring maximum reliability and precision.

“For 15 years we have only purchased machine tools with the BIG-PLUS system. Thanks to this advantage, we know that we can complete the required machining operations, and also that we can be ambitious and go further,” says Bronzino.

Autoblok and BIG KAISER have enjoyed a relationship for 20 years, particularly with regard to the production plants in the Italian territory. The partnership was initially directly with BIG DAISHOWA in Japan, and today, following the commercial reorganization of the group, it continues with BIG KAISER. Almost all in-house supplies to Autoblok are BIG Daishowa tool holders.

“20 years ago, we used other brands. The reason why we switched to BIG chucks is very simple: quality, precision, reliability and durability,” Bronzino explains. “Another feature that makes BIG DAISHOWA's products stand out from the competition is longer tool life.”

Need for boring satisfied

BIG KAISER’s range of boring tools has been used in Autoblok’s Susa Valley production facilities for about a year now. The introduction of BIG KAISER boring tools was born from a very precise technical requirement: to be able to ensure maximum repeatability and consistency, guaranteeing high performance that other manufacturers could not, even with a work piece that had problems of roundness and cylindricity.

The plant manager at Autoblok, who uses the boring system, shows no hesitation in highlighting the advantages of BIG KAISER boring bars. “The digital display of the BIG KAISER heads allows us to easily correct the dimension and fully comply with the tolerances. Thanks to the extended range of BIG KAISER heads we can often use only one tool for the entire machining cycle, saving a lot of time. In addition, they offer unparalleled rigidity.”

On large production and finishing machines, only BIG KAISER spindles are used. The impetus for the massive changeover to BIG spindles came around 2008, when FMS (flexible manufacturing systems) were introduced at Autoblok with machines with a stock of more than 200 tools. Since then, all new machine tools introduced in Autoblok have between 240 and 320 tools.

Pier Domenico Bronzino has no doubts: “The quality of the product can be seen immediately, even just by touching it. In addition, in finishing, the precision of the execution is evident, a fundamental requirement when you find yourself having to ‘split pennies.’“